The current reality in our country is that there is a very serious water shortage that is driving us to develop a new culture around this valuable resource. We simply cannot wait any longer, extraordinary measures are required.

INDUSTRIAS TEIXIDO SA is located in the municipality of Riudecols, in the county of Baix Camp, Tarragona. Like practically every other place in the region, Riudecols is undergoing a serious water shortage, one which is becoming increasingly worrying due to the continuing lack of rain.

Water is, and always has been, one of nature’s most precious resources, one which it is ever more important to preserve. The current reality in our country that there is a very serious water shortage that is driving us to develop a new culture around this valuable resource. We simply cannot wait any longer, extraordinary measures are required to ensure a reduction in water use by industry.

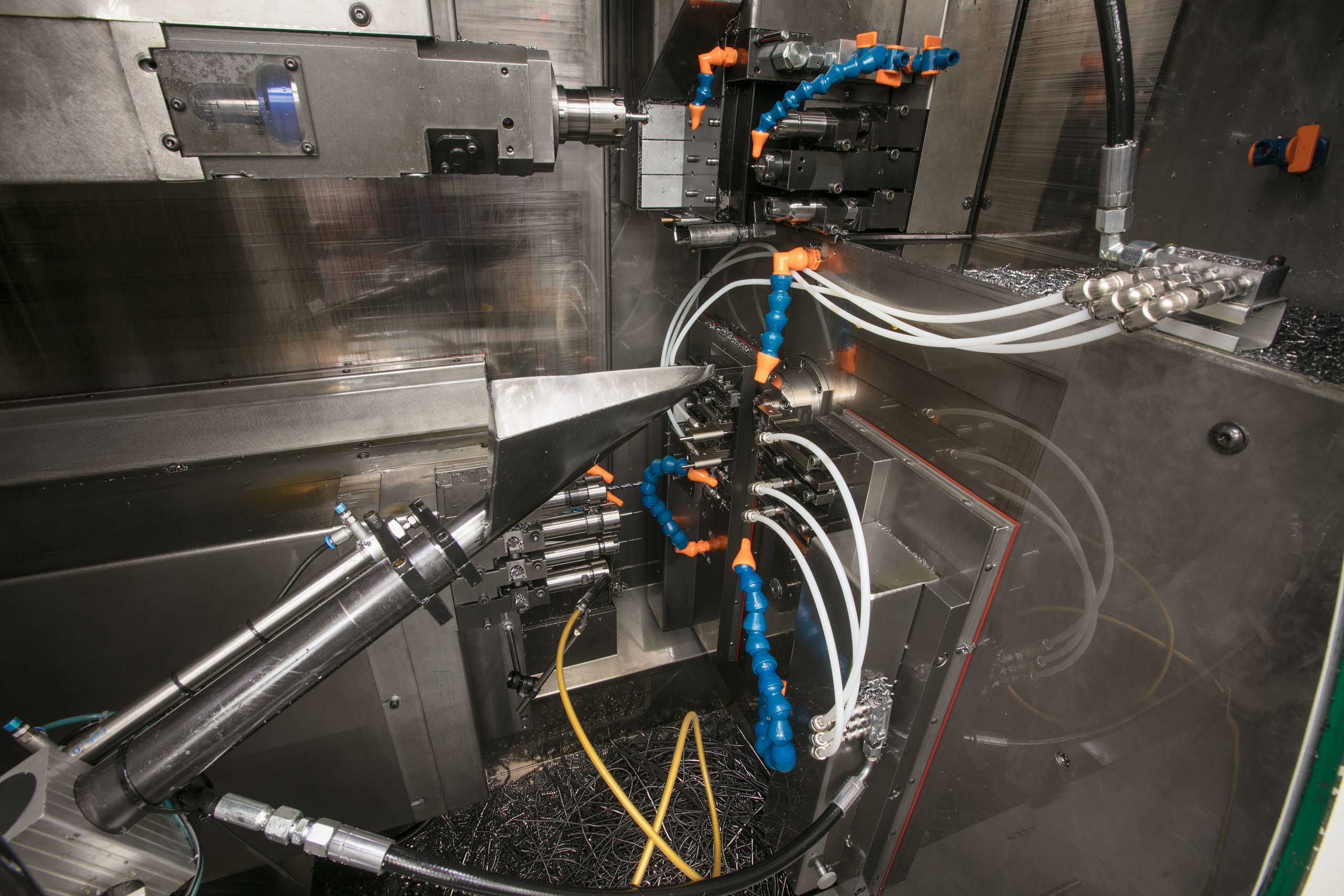

At INDUSTRIAS TEIXIDÓ, SA, we get our water supply directly from groundwater, and we have been observing how the water table of the aquifer is getting lower and lower. Among our processes, the ones that most require water are superficial treatments, where we cover our products electrolytically or chemically, as well as vibration treatments, in which we polish and shine the products. These processes absolutely require water.

We cannot find ourselves in a position where we have no water, which is why reducing our water consumption and reusing water are vital aspects of our environmental policy. In fact, the company has been working on aspects relating to optimising and reducing water use since 2017, modifying aspects that guarantee more efficient water usage through the installation of meters at all points of use, installing reductors that help us to limit the use of sanitary water, as well as acquiring and installing water reuse systems in closed circuits that allow us to achieve significant reductions in the use of water for work processes.

So far, all these measures have allowed us to reduce our usage. However, this is a marathon rather than a sprint, one in which water shortages are gaining ground, and we need to continue to work hard and make firm commitments to achieve efficient use of the water cycle, turning it into a closed circuit, one in which reuse becomes a basic premise that helps us manage the use of water from aquifers, which is increasingly difficult to achieve.